Cost Effective and Durable Modular Polyurethane Screens

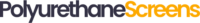

Polyurethane Modular Screens are used for the separation of Sand, Gravel, Granite, Quartzite, Limestone and Coal to name a few of the many applications. Our industry standard, cost effective and long lasting modular polyurethane screens are manufactured to client specifications (any size, shape or strength) being produced to fit unique requirements, equipment size and location. Best suited to wet processing applications. Polyurethane modular screens are an ideal material for screening, providing abrasion resistance and flexibility in order to avoid material build up.

Since the introduction of polyurethane modular systems, the use of polyurethane as a screening media has increased in popularity, predominantly down to the handleability, durability and ease of maintenance qualities that this material has to offer.

Versatility

Gap Technology have the in-house capabilities to manufacture and supply a number of different types of modular polyurethane screens to suit any conventional vibrating screen, new or old. They can also be moulded in several different shore hardness’s to suit the specific application.

Depending on the material to be screened and the parameters of the screening machine, softer modular screens can help to prevent clogging with terminal grains. This is achieved through adjusting the gap / hole widths and hole shapes.

Properties

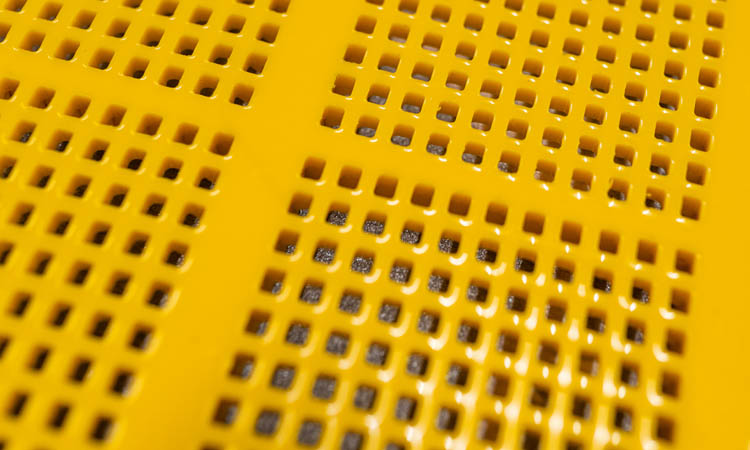

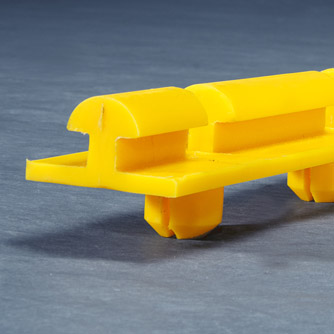

The fast fitting and demounting speed of our modular screen components reduces downtime and enables only the actually worn part of a screen fitting to be changed. This easy assembly and disassembly means shorter stoppages overall which in turn increases efficiency and productivity.

The noise-damping properties of polyurethane also reduces noise emission, improving working conditions. Official requirements with regard to environmental and occupational safety and health can therefore be met more easily.

Perfect alternative

Polyurethane screens apart from rubber screens make a perfect alternative for metal screens. Polyurethane screens have unique features thanks to A-type and B-type polyurethane elastomers combined with additional reinforcements.

Modular Polyurethane Screens are the best solution for mining, sand and gravel screening, compost / wood chip processing and aggregate-ore processing as they offer a similar open area ratio of woven wire screens but the polyurethane screens coating means that they last up to five times longer than steel meshes.

Modular Screens. Strength & Resistance

With a high strength polyurethane coating and an extremely wear and tear resistant surface, the Modular Screens are manufactured with reinforcement bars parallel to the panel width. Modular Polyurethane Screens are a cost effective modular system achieving optimal results mainly used in applications to separate Gravel, Quartzite, Sand, Gravel, Limestone and Coal just to name a few. As an additional service, we also provide a substantial associated range of adapters and accessories. Contact us for details and enquiries.

| Description | Gap Technology provides all available and known polyurethane modular system screens configurations and specifications. |

| Application | Classification of natural aggregates by using natural wet and dry screening method, classification, enrichment, dewatering of the broken aggregates, coal, ore, cinder, and other grain materials. |

| Material | A-type and B-type polyurethane elastomer, 45-95 Shore hardness. Additional steel reinforcements. |

| Apertures size | 0.30mm – 160 mm (square, oblong) The meshes are available in straight and staggered. |

| Thickness | 30 – 50 mm. |

| Dimensions | Common dimension of modules: 300mm x 1000mm for central modules, for side modules according to the sorter’s dimensions. |

| Assembly | Assembly is possible in all currently functioning fastening systems, available the whole range of polyurethane adaptors. |

Key Benefits

Extended life of the screen through high abrasion resistant and lack of the corrosion. Increased effectiveness thanks to the effect of self cleaning and conical shape of the mesh. Improved working conditions through noise reduction properties. Increased cost-effectiveness through easiness of the assembly and disassembly means shorter stoppage / possibility of exchange the elements of the screen deck construction / dimensions are adapted to sizes of the sorting devices. Increased precision of the screening process thanks to the right selection of the parameter’s screen: Size of meshes: 0.30mm-140mm (the wide range of granulation) · shape of meshes: square, oblong, round · system of meshes: regular, staggered · shore hardness: 45-95.

Product Range

Our extensive tension and modular polyurethane screens product range of spare and wear parts for use in sand and gravel processing as well as in quarries includes…

Plastic tensioning and plaining belts · Plastic module systems · Fastening elements such as adapters, wedges, side rails etc · Rubber sieves · Stamped membrane mats in many designs · Wire screen in various types of web and tension · Wire harness filters in all common variants · Perforated sheets of all types · Spare parts for crushers, impact, horizontal, rod-type mills and gravel-washings.

For information and enquiries, contact us

Associated Terminology

Industry terminology tends to vary a little depending on the industry sector. Commonly referred to as Polyurethane Screens, it’s quite common to come across these term variations:

Polyurethane Screens / Polyurethane Modular Screens / Modular Polyurethane Screens / Polyurethane Tension Screens / Polyurethane Mesh / Polyurethane Screening Panels / Polyurethane Screen Deck / Polyurethane Screen Mesh / Polyurethane Vibrating Screens / Polyurethane Screen for Mining Industry / Polyurethane Screen for Quarrying Industry.

Accessories & Adapters

Polyurethane Standard Adapter

Polyurethane Adapter 7/9 Pin

Polyurethane Screwed Sidebar

Polyurethane Wall Fitted Adapter

Polyurethane Integrated Sidebar

Polyurethane Fixing Peg

Polyurethane Classic Sidebar / Sideliner with Wedge

Polyurethane Adapter 7/9 Pin with Support

Polyurethane Adapter for T Profile