Tensioned Polyurethane Screens for Superior Screening Efficiency

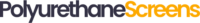

Polyurethane Tensioned Screens are available in a wide range of apertures and shore hardness’s, providing a high wear and corrosive resistant screen media for a range of applications from scalping to dewatering. Superior screening efficiency over conventional screening media is achieved through substantially lower noise levels compared to standard woven wire screens. Whilst the abrasion & impact resistance properties that tensioned screen mats brings also helps to increase product longevity.

Overall, polyurethane tensioned screen panels from Gap Technology represent some of the best screening solutions for those applications that require an excellent elevated screening performance with a high wear resistance in every brand and model of vibrating screen.

Properties

Tensioned polyurethane screens offer the highest screening efficiency available. Concerning both wet and dry aggregate separation, they are the most modern, cost effective way of achieving improved productivity at reduced maintenance cost.

Properties include, but are not limited to:

- Longest wear life of any known material.

- High screening efficiency.

- Cost effectiveness guaranteed.

- Fitted conventionally without machine alteration.

- Unique tensioning design ensures proper fit.

- Machine frame protection built into design.

- Environmentally acceptable-reduces noise factor.

- Corrosion proof.

Replacement

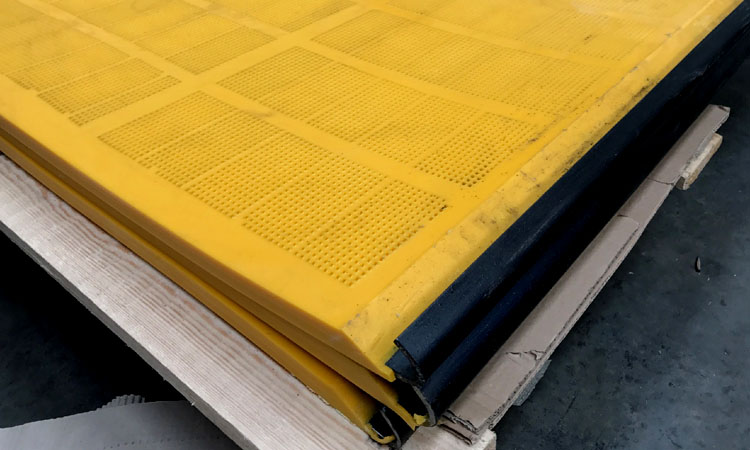

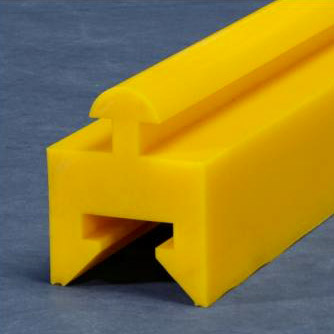

Polyurethane tensioned screens mats can directly replace metallic meshes, woven wire or rubber screen cloths utilizing the same fixings (without having to modify or adapt the machine). Tensioned over camber bars that have rubber capping and fastened in place using tensioning clamps, these tension screens are built with metallic cable reinforcement to absorb tension and thus increase resistance to strain and load.

They then are one of the quickest and easiest ways to take advantage of the benefits of a polyurethane screen media without having to go to the expense of converting a screen to a modular system.

These types of screen mat are made to order, so can be tailored to fit any screen that has been setup for tension based screen media.

Customisation

Gap Technology manufacture tensioned polyurethane screens to custom installations, configured to single or double crown, side tensioned, flat clamped or end tensioned for any screening application and end user requirements.

If you are looking for particular screen solution to unique specifications, we will require the following details:

- Material to be screened.

- Separation size.

- Feed quantity per hour.

- Sieve analysis.

- Wet or dry (moisture content).

- Length and width of machine.

- Custom enquiries

Tensioned Screens For Coarse, Medium & Fine Screening

Fitted to pre-existing vibrating screens, our polyurethane tension screens are an ideal and cost effective alternative to metal, with improved productivity when used in the separation of aggregates in both dry and wet conditions. In fact, our manufacturing system combined with the extraordinary technological characteristics of polyurethane, make them an ideal solution for coarse, medium and fine material screening. Gap Technology can also provides Adapters and Accessories for the Polyurethane Plain and Tension Screens. Contact us for details and enquiries.

| Description | Gap Technology provides polyurethane screens lengthwise and crosswise tensioned. Polyurethane area is produced in individual sizes. |

| Application | Clasification of the natural aggregates by using natural wet and dry screening method, classification, enrichment, dewatering of the broken aggregates, coal, ore, cinder and other grainy materials. |

| Material | A-type and B-type polyurethane elastomer, 45-95 Shore hardness. Additional steel reinforcements. |

| Apertures size | 1.1mm – 160 mm (square, oblong) Regular and staggered. |

| Thickness | 20 – 60 mm. |

| Dimensions | Max 1900 – 3000 |

| Assembly | Assembly is possible without exchange of the sorter’s frame, directly into the place of metal screens. The method of assembly of the polyurethane tensioned screens:

Tensioning through tensioning bars and hooks (pointed up for side tensioning and down for end tensioning). / Recommended rise of the supports: 20 mm/1 m. / Protective profiles on supports. / The screen can not be drilled (steel reinforcement could be damaged). |

Key Benefits

Extended life of the screen through high abrasion resistant and lack of the corrosion. Increased effectiveness thanks to the effect of self cleaning and conical shape of the mesh. Improved working conditions through noise reduction properties. Increased cost-effectiveness through easiness of the assembly and disassembly means shorter stoppage / possibility of exchange the elements of the screen deck construction / dimensions are adapted to sizes of the sorting devices. Increased precision of the screening process thanks to the right selection of the parameter’s screen: Size of meshes: 0.30mm-140mm (the wide range of granulation) · shape of meshes: square, oblong, round · system of meshes: regular, staggered · shore hardness: 45-95.

Product Range

Our extensive tension and modular polyurethane screens product range of spare and wear parts for use in sand and gravel processing as well as in quarries includes…

Plastic tensioning and plaining belts · Plastic module systems · Fastening elements such as adapters, wedges, side rails etc · Rubber sieves · Stamped membrane mats in many designs · Wire screen in various types of web and tension · Wire harness filters in all common variants · Perforated sheets of all types · Spare parts for crushers, impact, horizontal, rod-type mills and gravel-washings.

For information and enquiries, contact us

Associated Terminology

Industry terminology tends to vary a little depending on the industry sector. Commonly referred to as Polyurethane Screens, it’s quite common to come across these term variations:

Polyurethane Screens / Polyurethane Modular Screens / Modular Polyurethane Screens / Polyurethane Tension Screens / Polyurethane Mesh / Polyurethane Screening Panels / Polyurethane Screen Deck / Polyurethane Screen Mesh / Polyurethane Vibrating Screens / Polyurethane Screen for Mining Industry / Polyurethane Screen for Quarrying Industry.

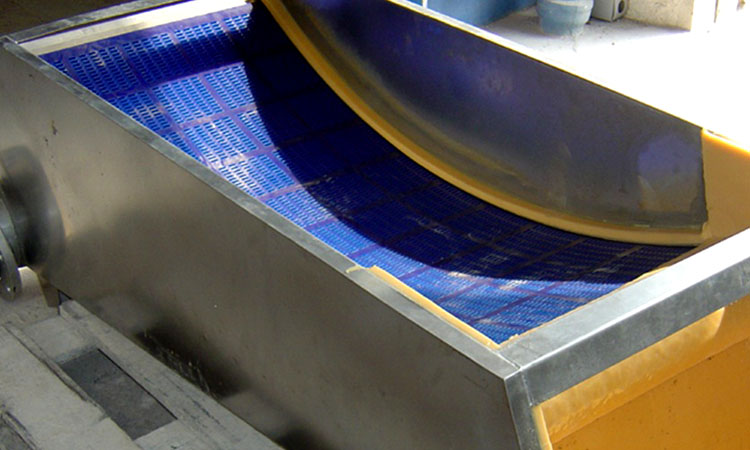

Accessories & Adapters

Polyurethane Standard Adapter

Polyurethane Adapter 7/9 Pin

Polyurethane Screwed Sidebar

Polyurethane Wall Fitted Adapter

Polyurethane Integrated Sidebar

Polyurethane Fixing Peg

Polyurethane Classic Sidebar / Sideliner with Wedge

Polyurethane Adapter 7/9 Pin with Support

Polyurethane Adapter for T Profile